Vector Fins™

Increased onboard comfort

Increased onboard safety

Increased boat value

Less overall fuel consumption

A game-changer in advanced

yacht stabilization

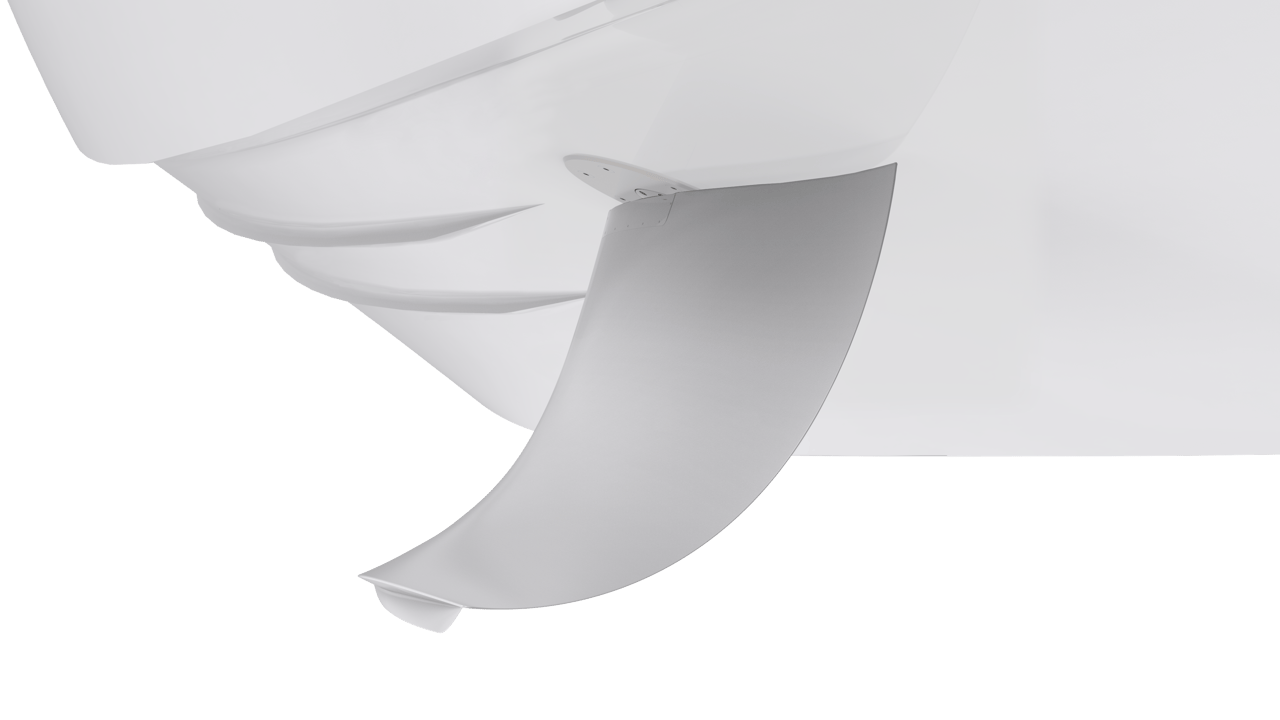

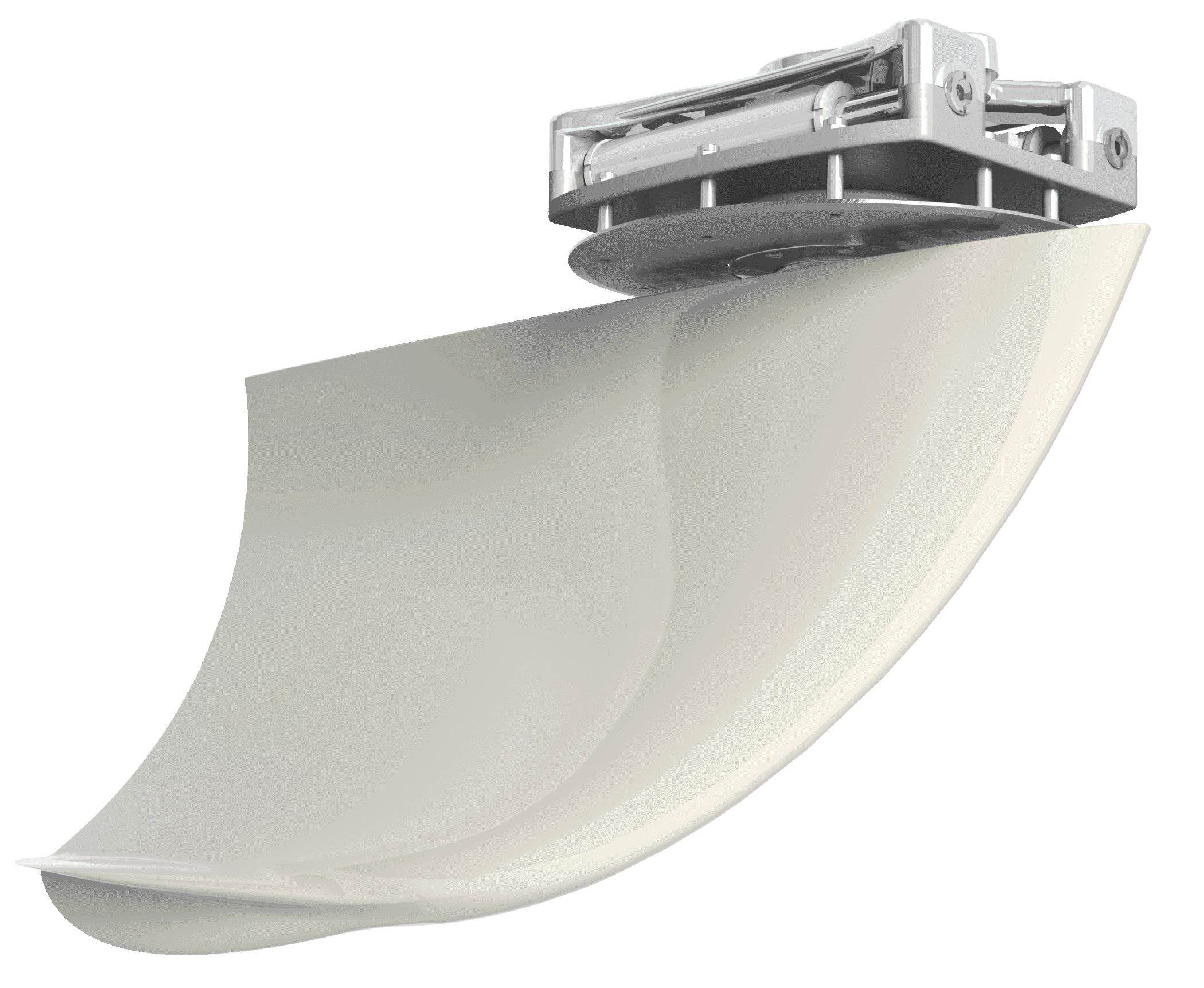

Vector fins™ is the only top-performing stabilizer system for both cruising and at-anchor use. The fins' unique shape reduces drag and improves fuel efficiency, translating more power into actual roll stabilization.

One of the problems with traditional flat fin stabilizers is that on most v-shaped hulls, the force vector applied to stabilize the vessels is too close to the horizontal plane. This means that a lot of the applied energy goes to waste when pushing the hull sideways and impacting yaw.

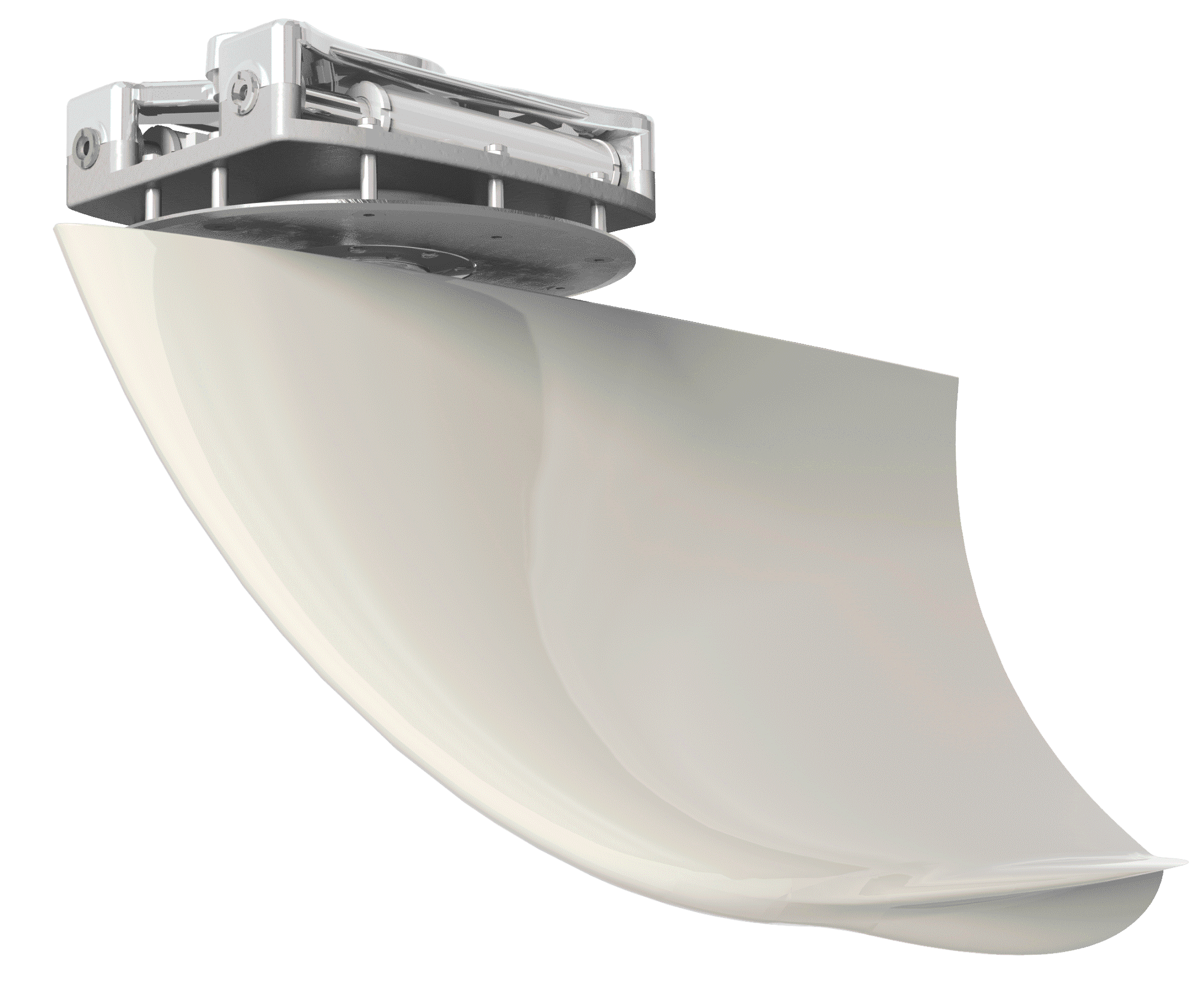

With winglets similar to what is used on modern aircraft, Vector Fins™ adjusts the force vector closer to the vertical plane. This unique design allows using smaller Vector Fins™ compared to larger straight fins to achieve the same results and significantly reduce unwanted side effects such as yaw and sway.

Another significant effect of the curved Vector Fins™ is that they create lift, reducing the hull's overall drag. In some high-speed yachts, the lift has offset the added drag completely, increasing top speed. The hydrodynamic lift generated by a fin is proportional to the square of its speed through the water, so a rise from 17 knots to 24 knots would double the lift from the fins.

It's like riding on a magic carpet.

- John Maxey, yacht owner

A revolutionary generation of

fin stabilizers

Vector Fins™ can be up to 30 percent more efficient underway and up to 50 percent more efficient at anchor. Undesirable side effects, such as yaw and sway, are reduced by up to 55 percent compared to traditional fin stabilizers.

Vector Fins™ stabilizers dramatically improve the roll reduction efficiency while at the same time reducing undesired yaw and sway motions.

The huge benefits in both efficiency and reduced side effects are beneficial for any type of boat. This is particularly relevant for modern fast cruisers, where traditional stabilizers typically have not performed the desired roll reduction without causing too many side effects.

The low weight and speed-efficient hull design cause short natural roll periods while being easier affected by sway and yaw motions. These hull designs follow the waves more rigidly and require more stabilization force to be applied faster due to the shorter roll periods.

A simple solution to a complex problem

The vertical concave shape redirects

the force direction and operates in an

up-and-down motion, unlike flat fins that work with forces parallel to the hull angle.

Effectively, more of the force benefits roll reduction, and less is wasted yaw and sway.

By this multidirectional force angle, the leverage arm around the boat's rolling point also improves roll reduction by increasing the boat's physical resistance to water motion. Therefore with a smaller set of Vector Fins, you will see improved results in drag, power consumption, internal space consumption, and mechanical load-bearing compared to a set of flat fins of greater size.

Up to 55% fewer side effects than conventional

stabilizer systems

Up to 30% more efficient underway than flat fins

Underway

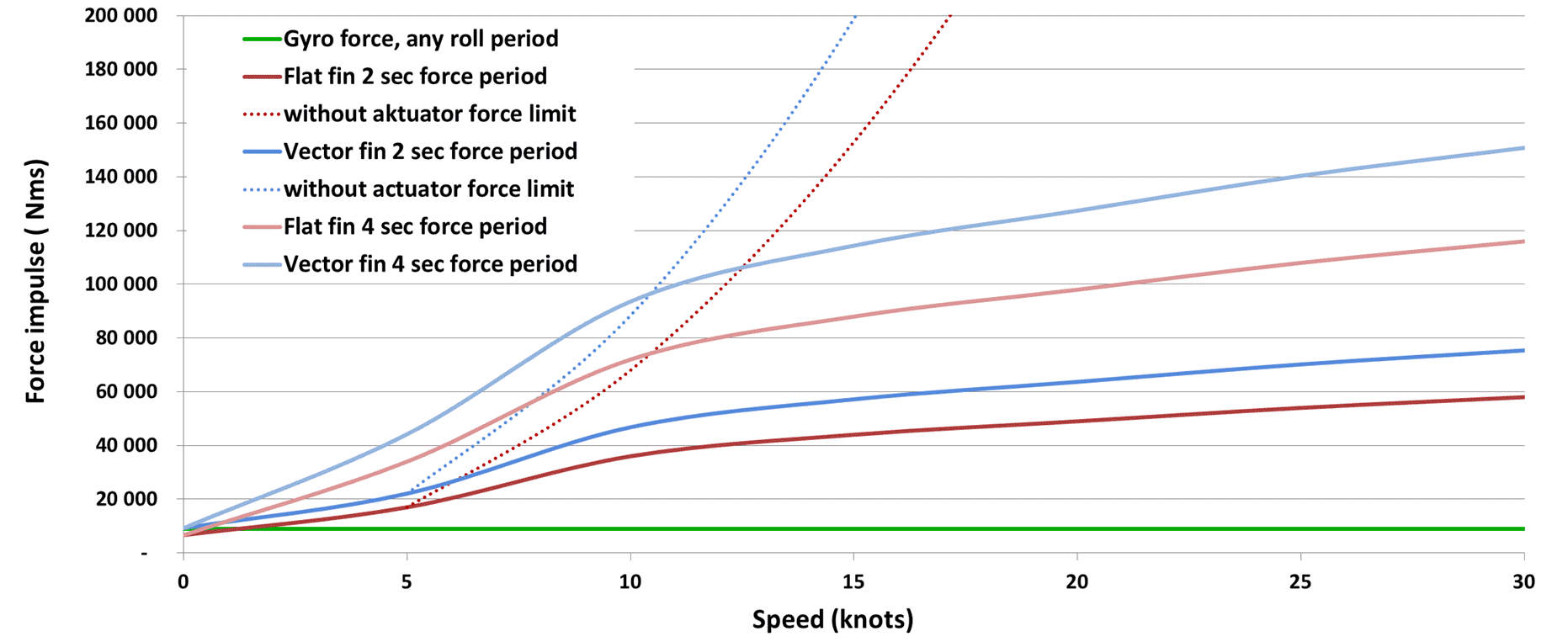

Contrary to gyro stabilizers that lose efficiency while underway, Vector Fins™ increases stabilization force and improves when increasing speed by lifting the vessel higher in the water, reducing its total water displacement.

Standard flat fin stabilizers cannot utilize this potential because they are naturally limited by the excessive water force on the fins, creating drag and preventing the actuator from rotating the fins to higher angles.

During heavy seas, the Vector Fins™ design counter the length of roll periods of standard flat fins. This is a substantial benefit as bigger waves are typically longer. Extensive testing has shown while underway, Vector Fins™ consistently improves roll reduction efficiency by about 30 percent compared to standard flat fins of the same size.

Due to the Vector Fins™ unmatched efficiency, the system can reduce the uncomfortable rolling motion of the boat up to 95% while cruising even in relatively large waves, keeping you and your guests comfortable and safe on board.

Up to 50% more efficient at anchor than flat fins

At Anchor

As most boat owners spend more time at anchor than underway, the stabilization system must perform well at any speed, including no speed.

A stabilized boat offers a significant increase in onboard well-being. Moving around, getting the tender out, serving dinner, or just getting in and out of the water for swimming becomes a lot easier and safer from a stabilized boat.

A sound any speed stabilization system allows for comfortable use of your boat when you otherwise would, or at least should, have stayed in port.

Vector Fins™ has proven to be up to 50% more efficient than flat fin stabilizer systems while at anchor. With actuators that ensure quiet operation, you can spend those amazing nights under the stars in a bay instead of in a busy harbor.

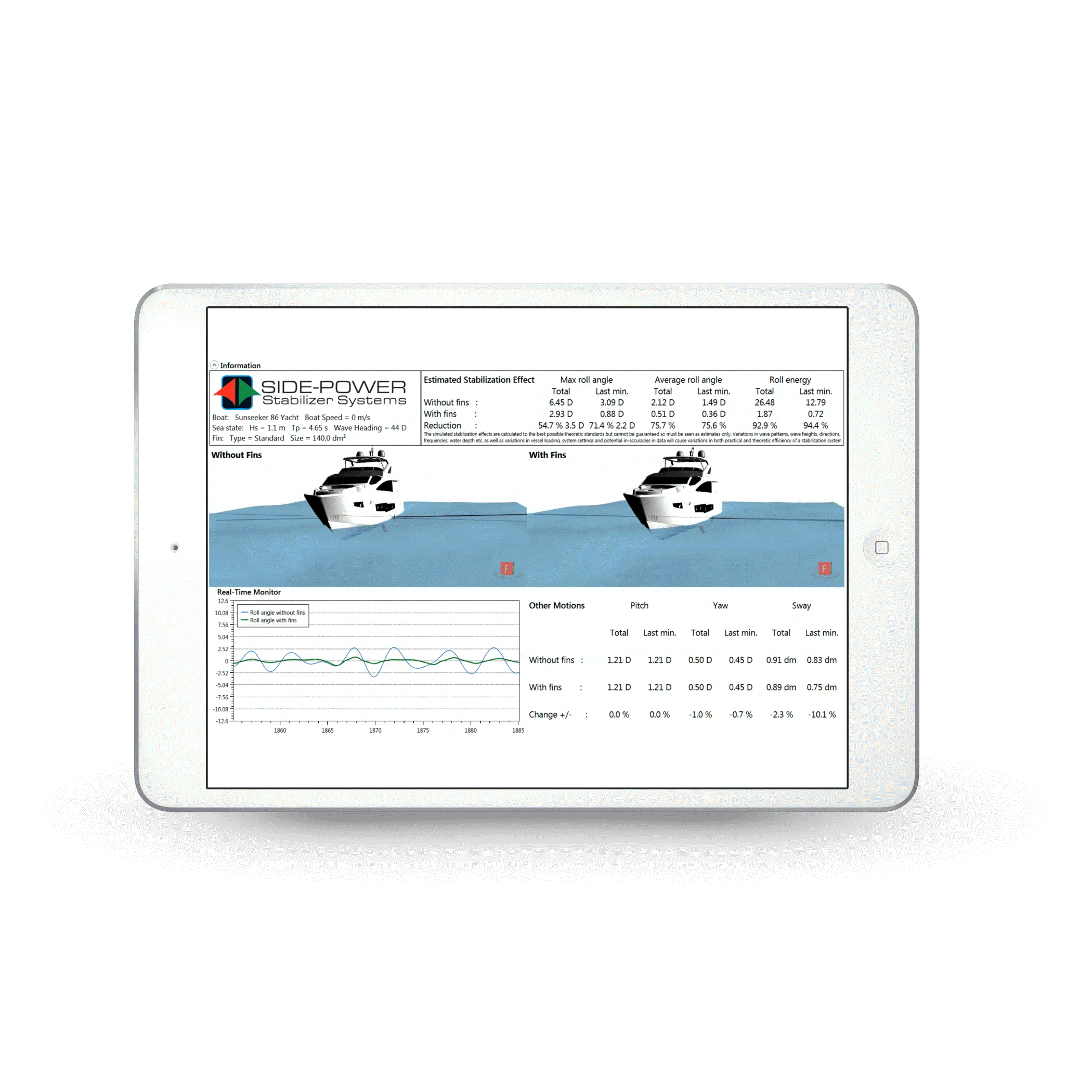

Verified stabilization test results

Princess 56 with 0.6m Vector Fins™

Cruising, 11 knots

At anchor

No stabilizer

Vector fins™

Reduction of roll

Reduction of seasickness

Max roll movement

Max roll angle

10.4°

9.4°

97%

72%

99.8%

92%

99.8%

88%

97%

66%

0.3°

2.6°

0.15°

1.4°

5.7°

4.1 °

Average roll movement

Average roll angle

No loss of speed

Vector Fins™ create as much lift as they add drag, resulting in virtually no loss of speed and thereby no added fuel costs.

Features

Up to 50 percent more efficient than flat fins

Up to 55 percent fewer side effects than flat fins

Advanced hydrodynamic design

20-50 percent less resistance than other fins, resulting in virtually no loss of speed, and thereby no added fuel costs

All Vector Fins™ are prepared for high efficiency in any speed 2:1 size ratio, also at anchor

Vector Fins™ are formed as a one-shot vacuum injected vinyl ester process over pre-shaped core material using a closed mold method.

Designed with rowing and mat layers, a technique that ensures maximum strength and minimum weight, the fins can even withstand minor damages without disintegrating.

Up to

50%

more

efficient

Up to

55%

less side effects

Unlike gyro stabilizers, efficiency increases with speed

Minimal to no increase in fuel consumption

Minimal to no loss of speed

Silent all-night operation

Suitable for retrofit

Benefits

Research and development

Sleipner continuously invests in making our solutions better. We develop systems designed to integrate with existing and future technology. Many of the products we produce are designed for the large yacht and commercial industry. Still, they have perfect applications on all kinds of vessels.

Floating lab

Our 58 feet test vessel with a top speed of 37 knots, fully loaded with advanced

sensors and logging facilities for data collection and analysis.

Controller intelligence

Continuous development of the best control software possible, cooperating with leading companies in control technologies

Color touch panel for ease of use and control

Self-adjusting advanced algorithms and any speed functions for stabilization at anchor

Easy upgrade of software ensures future compatibility and improvements

Reverse gear position input but also other sensors to safeguard that fins are centered and locked immediately if the boat is starting to move backward

GPS speed input (no shaft sensor) helps control algorithms do the best possible job.

S-Link™ integrates common intelligence with thruster systems and central hydraulics

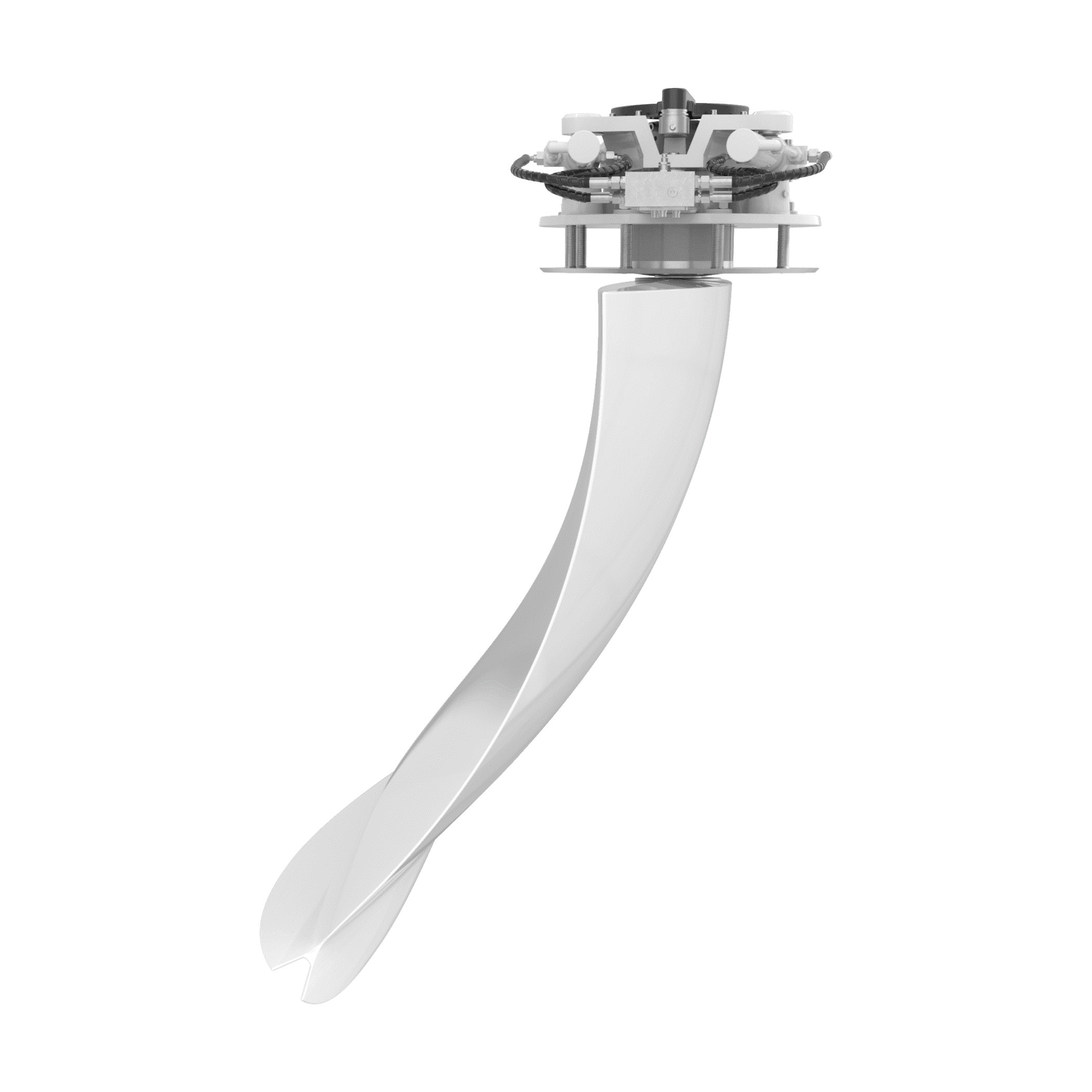

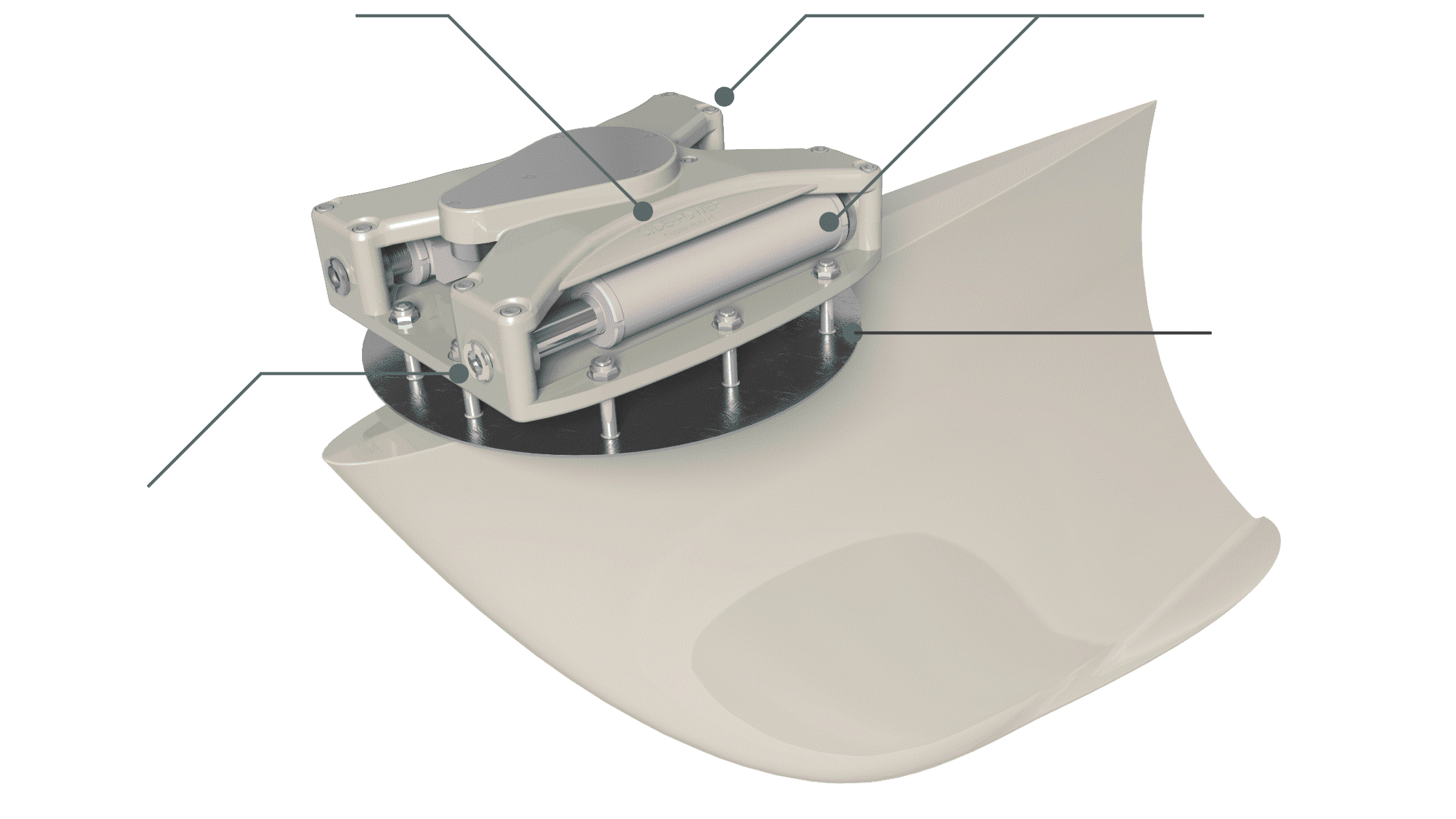

SPS55 Actuator

The SPS55 actuators for Vector Fins™ are incredibly compact and silent, designed to fit in the small available spaces in modern boats below 70 feet/50 meters where living space is prioritized.

Designed to satisfy the needs of owner-operated vessels with a total focus on reliability and hassle-free operation, these actuators ensure quiet operation suitable for installation below the floor in livings spaces.

No moving hoses

Rack and

pinion drive connection

Symmetrically balanced

All external parts in stainless steel

Construction

The squared base plate provides a large load distribution area to the hull while still enabling installation in tight spaces between stringers and bulkheads

Dual, balanced cylinders provide symmetrical load and force

The actuator can be installed in any direction in the boat. The fin angle is independent of the actuator

No moving hoses secure against leakages and potential wear, as well as simplifying installation

Oversized bearings for lifetime operation with only a minimal level of maintenance

Rack and pinion drive connection for quiet, reliable, long-life operation, with easy service when needed after thousands of operational hours

Vector Fins™ are conveniently mounted/removed from the outside of the hull, convenient for transport or other haul-out situations where this might be needed

Defined shaft-shear point in case accidentally hitting something

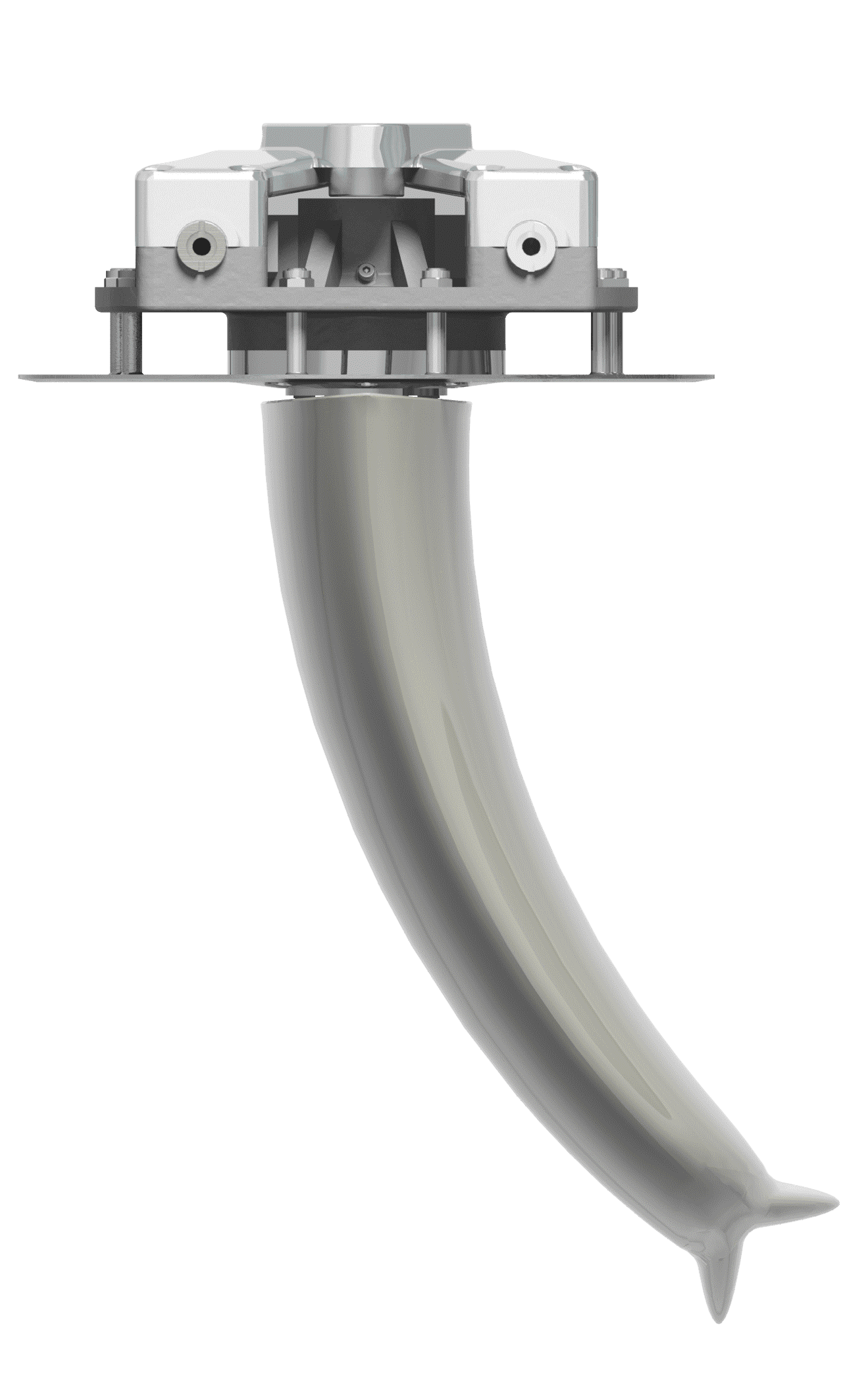

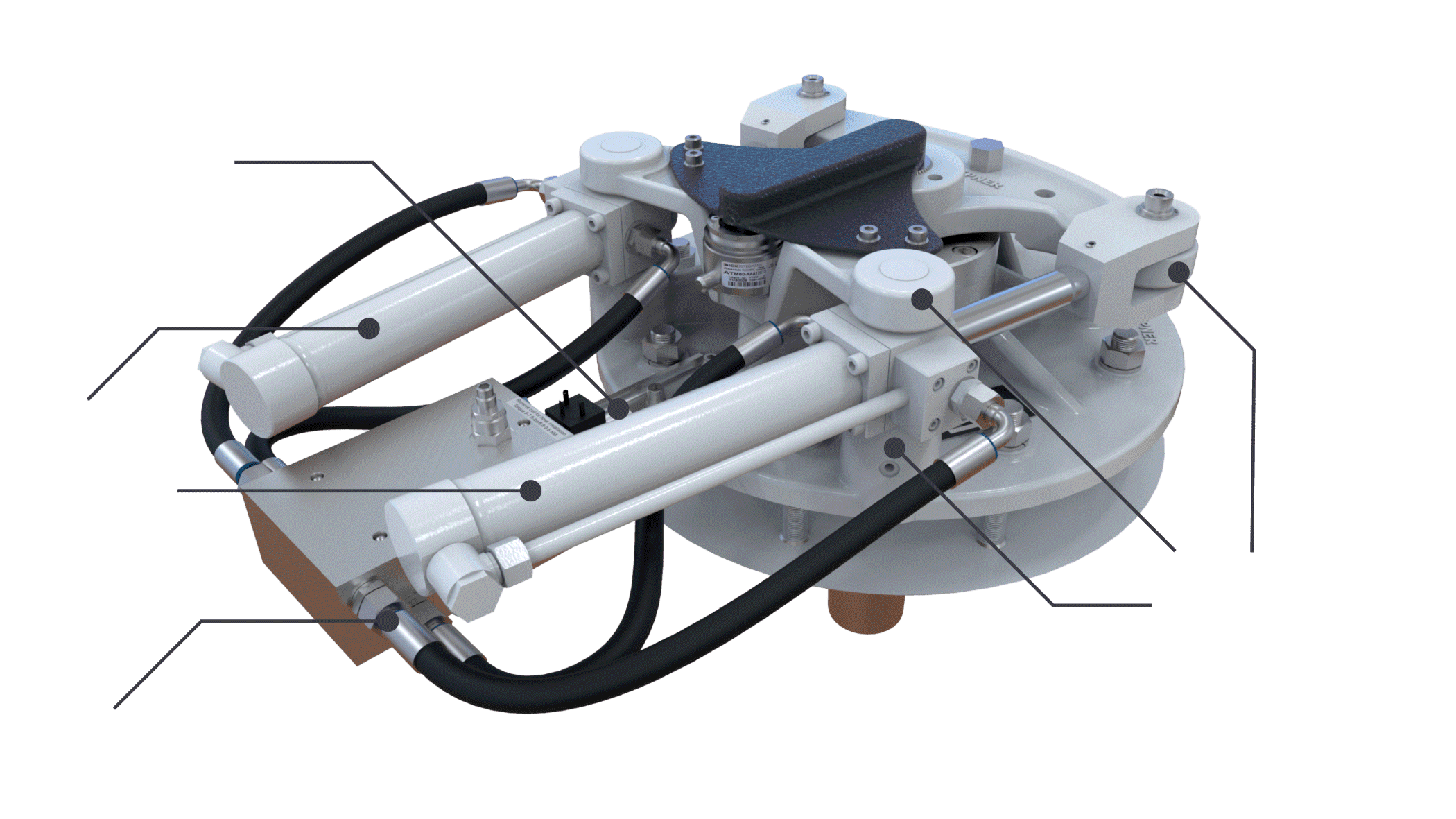

SPS66 / SPS92 / SPS93 Actuators

Utilizing the space available effectively in larger boats is often a key factor when installing a stabilizer system. Our larger range actuators are 25-75 percent lower in height than standard models on the market.

All moving hydraulic connections are pre-fitted

Dual hydraulic cylinder setup for symmetrical

loads

Non-moving attachment points for hydraulic hoses

Lifetime lubricated high-end bearings, no need to grease bearings periodically

Construction

Constructed for easy installation and minimal noise reproduction

Precision machining and assembly secures a long lifetime and durability

No additional center lock. This is automatic in the standard hydraulic system - very safe due to the hydraulics having extreme safety limits

Dual balanced cylinders provide symmetrical load and force:

- Balanced load single-cylinder solutions

- Less bearing load, thereby allowing for a more compact shaft bearing assemblyPurpose-designed dual shaft sealing, superior to standard simmer ring lip seals.

Pre-fitted internal hydraulic connections on actuators, the installer only connects non moving hoses/pipes - safe and easy.

No complex adjustments are required to set up controller with lots of factors. These are set automatically on the first sea trial of the boat

Defined shaft-shear point in case of the fins accidentally hitting something

Lifetime lubricated high-end bearings as standard, saving time and money for the owner. Most stabilizer systems require you to periodically service their bearings, meaning either a part change, lubrication, and/or mechanical adjustments

Vector Fins™ are conveniently mounted/removed from the outside of the hull, convenient for transport or other haul-out situations where this might be needed

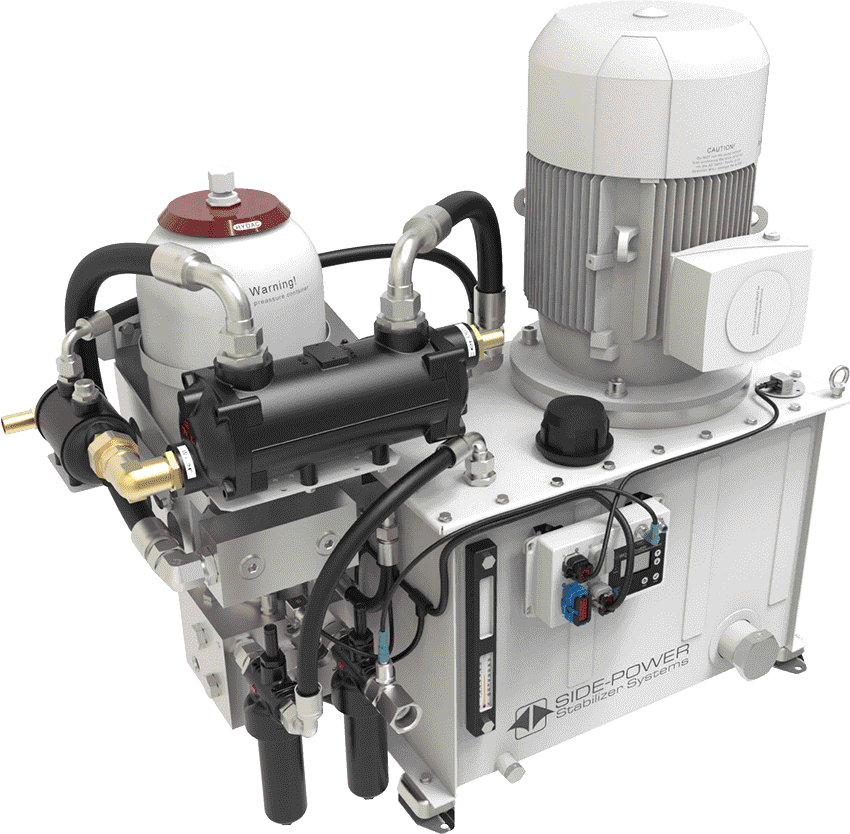

Standalone hydraulic power pack

The compact power packs can run the stabilizers from the generator power at all times. You can also use the stabilizers underway with the generator shut down by adding an optional load sense pump.

Compact,

quiet

and easy

to install

This is a complete hydraulic power unit (HPU) for installations where the vessel does not have a hydraulic thruster system. All of the hose and wire connections are pre-installed, allowing for faster system install and startup in the field. All connections are focused on two sides of the tank, allowing installation in confined spaces.

Sleipner offers similar pre-connected and easy-to-install central hydraulic systems when other hydraulic consumers, typically thrusters, are required. These have an equivalent level of integration while, of course, being a bit larger due to the higher capacities required by thruster systems. When combined with a hydraulic thruster system, the stabilizers and thrusters communicate via an S-Link™ CAN-bus system, enabling automatic power distribution to where it is needed at the time and stabilizer control from the inexpensive thruster control panels.