- Home

- Thruster systems

- Thrusters

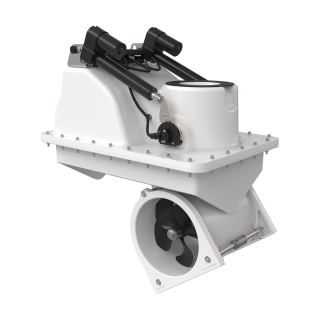

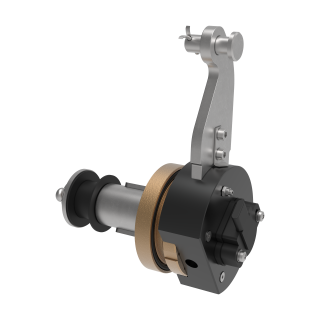

- SRHP320 retract thruster hydraulic G16

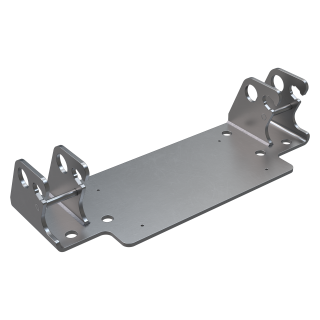

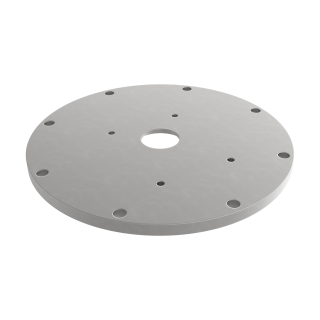

Unless you vessel is prepared from the builder with a custom base, you will need the mold-in base for installing your retract.

Thrusters

SRHP320 retract thruster hydraulic G16

320kg thrust, 16cm³

-

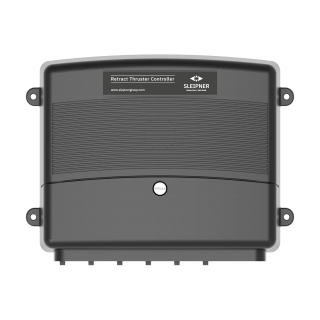

S-LINK™

S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel.

- Compact and waterproof plugs

- Keyed and color-coded connectors to ensure correct and easy installation

- Different cable lengths, extenders and T-connectors makes the system scalable and flexible to install

-

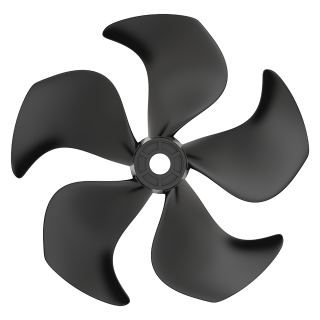

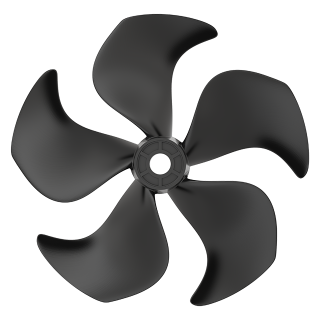

Q-PROP™

The Q-PROP™ has measured noise reductions of up to 75% in controlled environments. The five-bladed skew propeller reduces noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust power.

- The expected noise reduction in average installations: 20-40%

- Upgrade kits are available for most Sleipner thruster models with special adaptors

-

PRO™

A PRO™ thruster system enables you to apply only the necessary power to complete your maneuver. The variable speed control eliminates the noise associated with standard on/off thrusters.

The system also includes a practical hold-function. In a dual system (bow and stern) a single press of a button will keep you alongside the docks - making docking truly a one-person job.

Speed controlled thrusters are the best choice for joystick interaction. -

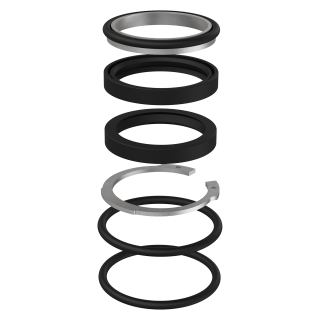

SEALED DRIVE LUBRICATION

The thruster gearleg is pre-filled for lifetime lubrication and sealed using a long-time mechanical seal with ceramic and carbon surfaces for ultimate security against water intrusion.

-

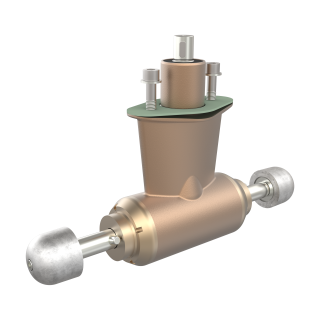

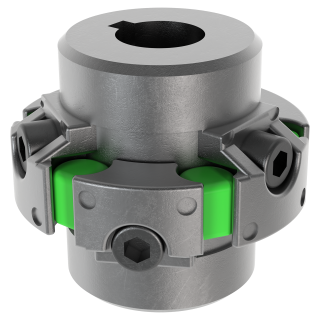

FLEXIBLE COUPLING

Flexible coupling protects the product’s driveline by compensating for minor misalignments between the shafts of the thruster motor and gearleg.

-

TWIN COUNTER-ROTATING PROPELLERS

Two counter-rotating propellers offer the most thrust at a good performance ratio in a minimal tunnel diameter. This system is used in our larger thrusters for maximum power. Our twin-counter thruster range is the favorite among leading boatbuilders in high-end yachts.

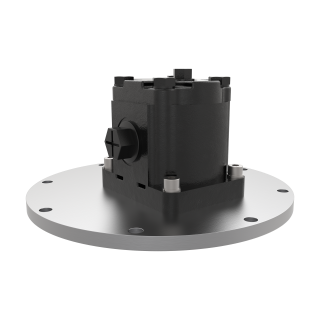

Item code: SRHP320/300TC-G16

SHRP320 is a sturdy retract thruster with 320 kg of thrust, suitable for boats between 72-110 feet/ 22-34 meters. It can be mounted as a bow or stern thruster.

The thruster is mounted on a flange and has a fast deployment and retraction time. The unit is compact, making it perfect for boats with limited height space.

A remote control is a popular accessory. See some of the important product and safety features below.

Retractable thrusters cause no drag

If you have a performance boat, sail, or power, and you're worried about the smallest amounts of drag, a retractable thruster is a perfect solution for you.

With power ranging from 100-1400 kg for installation in both the bow and stern, Sleipner offers a wide range of hydraulic retractable thrusters designed for commercial vessels and larger leisure boats.

Sleipner's retractable thrusters work with all types of propulsion systems – DC, AC, and hydraulic – and can be installed in the bow and the stern of the boat. Available as standard (on/off) or PRO™ with variable speed control extending from 80 kg to 300 kg of thrust.

Like all Sleipner products, the retractable thrusters are made with high safety standards. Safety is important in product design, from build quality to ease of installation, to ensure long-term reliability.

There are three versions of the retractable thrusters, one designed to be directly molded in and two designed to be mounted on a flange. The flange can be a mold-in base from Sleipner, or boat builders can use materials suitable for their hull or as part of their hull design.

The flange-mounted models have the thruster unit placed in a casing that can be bolted to a base. This makes installing the thrusters in hulls made from different materials easier. It also simplifies series production, as it avoids the need to mix laminating and engineering jobs.

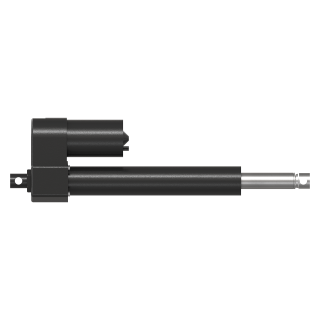

Quick deployment

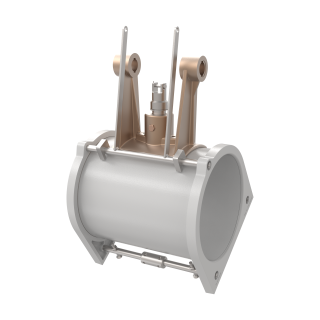

The thrusters with a tunnel diameter of 185 mm use one fast and powerful actuator. In comparison, the models with a diameter of 250 mm and 300 mm have two actuators to handle the increased forces while maintaining the same exceptionally fast deployment time.

Features

- Fitted as bow and/or stern thruster

- Quiet operation

- Plug & Play S-Link™ two way communication control cable wiring

- Motor assembly rigid mounted on retracting casing: no moving parts during retracting operation

- Compact size

- Reliable retracting mechanism avoids sticking

- Fast deployment

- Easy-to-use control panel with status feedback from thruster

- Available as PRO with variable speed control

The retract mechanism

The unique design of the underwater mechanism has only a few, but very solid parts, contributing to the stability of the unit. The unit's design makes the thruster as compact as possible while enabling safe use of heavier motors on more powerful units. The vertical installation of the motor (SRV) reduces shock forces on the unit in extreme waves compared to motors mounted at an angle.

A hydraulic thruster system

Sleipner offers complete hydraulic systems that are guaranteed to work well together and maintain high quality. These systems include all the necessary parts and are ready to be installed, ensuring the best possible quality.

Using a hydraulic system for multiple functions on a vessel can be a cost-effective choice. Once the main system is installed, adding a new function only requires adding a simple and relatively inexpensive hydraulic valve. This is more efficient and cheaper than using separate electric motors, solenoids, fuses, and battery switches for each function, especially for larger equipment.

Hydraulic valves and motors are also better suited for harsh environments such as the forepeak, bilge, transom, and ignition protection areas. Common hydraulic applications include thrusters, stabilizers, winches, capstans, cranes, and other equipment.

Sleipner's hydraulic systems are designed to provide excellent performance for the primary components and the flexibility to power multiple additional equipment.

Properties

S-LINK™

S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel.

- Compact and waterproof plugs

- Keyed and color-coded connectors to ensure correct and easy installation

- Different cable lengths, extenders and T-connectors makes the system scalable and flexible to install

Q-PROP™

The Q-PROP™ has measured noise reductions of up to 75% in controlled environments. The five-bladed skew propeller reduces noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust power.

- The expected noise reduction in average installations: 20-40%

- Upgrade kits are available for most Sleipner thruster models with special adaptors

PRO™

A PRO™ thruster system enables you to apply only the necessary power to complete your maneuver. The variable speed control eliminates the noise associated with standard on/off thrusters.

The system also includes a practical hold-function. In a dual system (bow and stern) a single press of a button will keep you alongside the docks - making docking truly a one-person job.

Speed controlled thrusters are the best choice for joystick interaction.

SEALED DRIVE LUBRICATION

The thruster gearleg is pre-filled for lifetime lubrication and sealed using a long-time mechanical seal with ceramic and carbon surfaces for ultimate security against water intrusion.

FLEXIBLE COUPLING

Flexible coupling protects the product’s driveline by compensating for minor misalignments between the shafts of the thruster motor and gearleg.

TWIN COUNTER-ROTATING PROPELLERS

Two counter-rotating propellers offer the most thrust at a good performance ratio in a minimal tunnel diameter. This system is used in our larger thrusters for maximum power. Our twin-counter thruster range is the favorite among leading boatbuilders in high-end yachts.

| Weight | Value |

|---|---|

| Net weight | 88kg / 194lbs |

| Dimensions | Value |

|---|---|

| (H) Height | 455mm / 17.9in |

| (L) Length | 843mm / 33.2in |

| (+L) Additional Length | 12mm / in |

| (W) Width | 580mm / 22.83in |

| (ID) Internal Diameter | 300mm / 11.8in |

| (WD) Water Depth | 300mm / 11.8in |

| (RD) Retract Depth | 445mm / 17.5in |

| (RW) Retract Width | 415mm / 16.3in |

| (MW) Mould Width | 477mm / in |

| (MH) Mould Height | 115mm / 4.5in |

| Flow rates | Value |

|---|---|

| 60% Flow rate | 32L/min / 8.47USG |

| 80% Flow rate | 36.9L/min / 9.76USG |

| 100% Flow rate | 41.3L/min / 10.93USG |

| Hydraulic | Value |

|---|---|

| Hydraulic motor system | G16 |

| Ideal vessel integration | Value |

|---|---|

| Typical vessel class | Sail boat |

| Typical vessel size | 22-34m / 72-110ft |

| Installation capability | Value |

|---|---|

| Bow Capability | Yes |

| Stern Capability | Yes |

| Retractable Capability | Yes |

| External Mounting Capability | No |

| Tunnel Capability | No |

| Motor | Value |

|---|---|

| Voltage electric motor | Hydraulic |

| Power Output | 20kW / 27hp |

| Performance | Value |

|---|---|

| Items operating power source | Hydraulic, Electric |

| Port | Value |

|---|---|

| Port A/B | 22L, Metric DIN 2353 |

| Drain port | 1/4" BSP |

| Pressure rates | Value |

|---|---|

| 60% Pressure rate | 152Bar / 2204PSI |

| 80% Pressure rate | 202Bar / 2929PSI |

| 100% Pressure rate | 253Bar / 3669PSI |

| Product Features | Value |

|---|---|

| Intelligent Power Control | No |

| Q-Propeller | Yes |

| Single Propeller | No |

| Twin Propellers | No |

| Twin Counter Rotating Propellers | Yes |

| Gravity Feed Lubrication | No |

| Sealed Drive Lubrication | Yes |

| Galvanic Separation | No |

| IP - Ignition Protection | No |

| PRO - Variable Speed Control | Yes |

| S-Link | Yes |

| Analog | No |

| Flexible Coupling | Yes |

| Safe Start-Up | No |

| Quick Stop | No |

| Hydraulic Pressure | Yes |

| At Sea Service | No |

| Hold Thrust | No |

| Ceramic Seals | No |

| Patented Design | No |

| Safety | Value |

|---|---|

| Safety features | Flexible coupling between hydraulic-motor and driveshaft protects gearsystem if propeller jams. If using the original Sidepower panel, the panel shuts off automatically 6 minutes after last use. An integrated microprocessor monitors solenoids, reducing wear and risk of solenoid lock-in. Auto-stop of the thruster in case of accidental solenoid lock-in or if run signal is continuous for more than 3 minutes Depending on the panel type after a certain time not in use, the console will shut down and retract the thruster. (NB: the thruster will retract automatically when turned off .) |

| Thrust ratings | Value |

|---|---|

| At light duty thrust | 320kg / 705lbs |

-

Installation Manual, SRHP (240, 320)

Installation ManualEnglishpdf -

User Manual, SRH Pro (SRHP)

User ManualEnglishpdf -

STP.fil SRHP320/300TC-G23 Retract - closed thruster - simplified

CAD FileEnglishstp -

XT.fil SRHP320/300TC-G23 Hyd. retract thruster - 3D simplified

CAD FileEnglishx-t -

STP.fil SRHP320/300TC-G23 Retract - open thruster Hydraulic

CAD FileEnglishstp -

DNV Type Approval Tunnel thruster

Conformity Certificate, Product sheetEnglishpdf -

Joystick integration overview for Sleipner thruster systems

Service/Support ManualEnglishpdf -

DNV AiP Thruster retract composite housing SR Ø250 and Ø300

Conformity CertificateEnglishpdf

SRHP320 retract thruster hydraulic G16

Guide to navigating spare parts

Below you will see the top-level assembly of spare part groupings available to you. If you desire a component within the presented assembly group, click on the name tag below the image to be directed to a detailed spare parts list for that assembly group. If no additional spare parts are available, it means that the current assembly group must be purchased as a whole due to service or installation requirements.

Hyd. motor 16 ccm

Cutting ring fitting

Hydr connection

1 Retract mechanical SRV300 Common

DIN 912 - M4 x 12

Cable actuator

DIN 125 - A 13

DIN EN ISO 1234 - 3,2x20

Locking bolt

DIN 913 - M4 x 20

DIN 985 - M4x0,7

M4 x 25 A4

DIN 127 - A 4

DIN 125 - A 4,3

ISO 10642 - M4 x 30

Cable SRV/SRH 300

2 Retract Horizontal Shaft Kit - 300mm

DIN 7991 - M4x12 A4

Parallel key DIN 6885

Lifting arm PS

DIN 125 - A 29

Lifting arm SB

Position marker

DIN 912 - M5 x 8

3 Upper vertical drive shaft kit SRV300

DIN 912 - M6 x 20

DIN 125 - A 6,4

Tool for ball bearing mounting

DIN 471 - 25x1,2

SKF 2RS1W 61805-2RS1

DIN 472 - 35 x 1,5

DIN 3760 - AS - 25 x 35 x 7 - NBR - Stainless

Slide bearing

Vertical drive shaft Assembly

DIN EN ISO 1234 - 3,2x12

Lower drive shaft joint

DIN 7 - 10 x 32 m6

DIN 6885 - A 6 x 6 x 20

Pin Ø8 L46,2

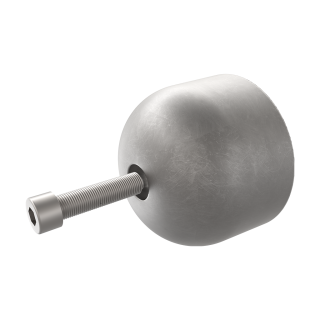

4 Anode kit, aluminium aloy (Al-Zn-In)

Alu anode

Bolt

5 Tunnel kit retract Ø300mm TC, complete

DIN EN ISO 1234 - 3,2x20

DIN 3771 - 48,9 x 2,62 - NBR

Turn ring Ø45

Wype Ring

Tunnel bracket

DIN EN ISO 1234 - 6,3x44

DIN EN ISO 1234 - 3,2x12

Ø8 x 46,2 mm

Lower drive shaft joint

DIN 7 - 10 x 32 m6

O-ring 12,5 x 1,8

Blind plug

Tunnel

Bushing for drive pins

6 Horizontal shaft sealing bushing kit

DIN EN ISO 1234 - 3,2x20

Sleeve bearing Ø50 ø45 L50

DIN 3771 - 48,9 x 2,62 - NBR

Turn ring Ø45

Wype Ring

Sleeve bearing Ø32 Ø28 L20

Thrust Washer Ø48 Ø28 W=1,5 8Igludur X)

DIN EN ISO 1234 - 6,3x44 (A4)

Pin Ø8 L46,2

DIN EN ISO 1234 - 3,2x12 (A4)

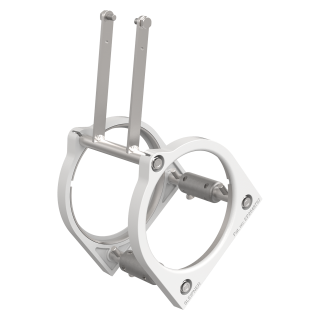

7 Retract ring kit Ø300mm

Sleeve bearing

Thrust washer

DIN 933 - M10 x 20 (A4)

DIN 934 - M10 (A4)

DIN 7991 - M10x70 A4

Connecting rod

Twist ring

DIN 125 - A 10,5 (A4)

DIN 985 - M10x1,5 (A4)

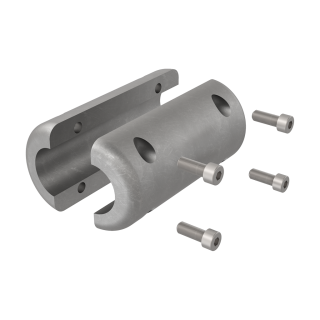

8 Gearleg SRV300 replacement kit

Bushing for drive pins

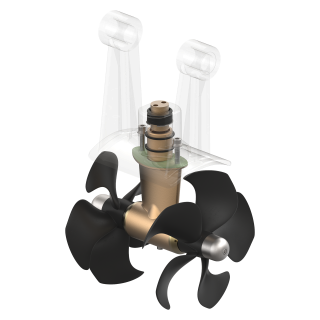

9 Gearleg SRV300TC w/out propeller

DIN 912 - M10 x 60

DIN 127 - A 10

DIN 125 - A 10,5

Bolt w/copper gasket

DIN 125 - A 17

DIN 985 - M16x2

10 Service kit retract 300mm

Wyper ring

O-ring 41,28x3,53

DIN 3760 - AS - 40 x 50 x 7 - NBR - Stainless

Inverted Internal Circlip DIN 5008 50x2

O-ring Ø50x4

Disclaimer

Sleipner warranties the original spare parts supplied only. The installer alone has responsibility for the installation of the spare parts. Do not attempt to fit replacement parts unless you are competent. If the spare part is fitted incorrectly, Sleipner Group will not be liable for any damage resulting.

The information given in the document was correct at the time it was published. However, Sleipner Group cannot accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifications without notice. Consequently, Sleipner Group cannot accept liability for any possible differences between product and document.

-

S-link is a Sleipner CAN BUS based control system with full intelligent communication between all devices within the system, much like a computer network. It is used for all retract thrusters and Pro thrusters with a DC control system.

Main advantages include:

• Round, compact and waterproof plugs with unique keying and color coding to avoid faulty hookups.

• An unlimited number of commands or information transfer on a single cable.

• It has user feedback to panel

• Intelligent troubleshooting

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.

-1.png)