- Home

- Thruster systems

- Thrusters

- SRVP100 PRO™ retract bow/stern thruster 24V

Thrusters

SRVP100 PRO™ retract bow/stern thruster 24V

100kg variable thrust

-

S-LINK™

S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel.

- Compact and waterproof plugs

- Keyed and color-coded connectors to ensure correct and easy installation

- Different cable lengths, extenders and T-connectors makes the system scalable and flexible to install

-

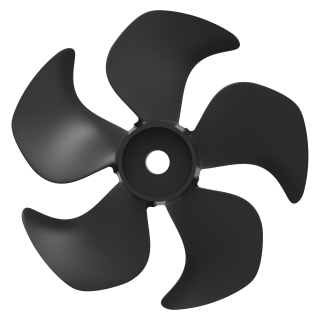

Q-PROP™

The Q-PROP™ has measured noise reductions of up to 75% in controlled environments. The five-bladed skew propeller reduces noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust power.

- The expected noise reduction in average installations: 20-40%

- Upgrade kits are available for most Sleipner thruster models with special adaptors

-

PRO™

A PRO™ thruster system enables you to apply only the necessary power to complete your maneuver. The variable speed control eliminates the noise associated with standard on/off thrusters.

The system also includes a practical hold-function. In a dual system (bow and stern) a single press of a button will keep you alongside the docks - making docking truly a one-person job.

Speed controlled thrusters are the best choice for joystick interaction. -

INTELLIGENT POWER CONTROL

Sleipner's patented intelligent power control provides a minimal delay between drive directions to reduce wear of the mechanical parts while monitoring solenoid functions. In the case of a solenoid lock-in, the thruster will automatically stop without extra user action or controlling the main switch.

-

OVERHEAT PROTECTION

When high temperatures are detected, On/off thrusters are automatically shut off to prevent overheating. PRO™ thrusters with speed control provide extended run-time by derating power to maintain temperature within safe levels.

-

GALVANIC SEPARATION

Immersed parts exposed to seawater are galvanic isolated from the onboard electrical system, eliminating stray currents.

-

SEALED DRIVE LUBRICATION

The thruster gearleg is pre-filled for lifetime lubrication and sealed using a long-time mechanical seal with ceramic and carbon surfaces for ultimate security against water intrusion.

-

FLEXIBLE COUPLING

Flexible coupling protects the product’s driveline by compensating for minor misalignments between the shafts of the thruster motor and gearleg.

-

TWIN PROPELLERS

Twin propellers can provide more thrust than a single propeller system in the same tunnel diameter. We use this system in our mid-range models, where high thrust is required in small tunnel diameters. Due to the compact design and high performance, the twin models have become the thrusters of choice among boatbuilders worldwide.

Item code: SRVP100/185T-24V

SRVP100 PRO™ with variable speed control is a sturdy retract thruster with 100-116 kg thrust, suitable for boats between 35-55 feet.

The thruster is mounted on a flange and has a fast deployment and retraction time. The unit is designed for vertical installation, making it perfect for boats with available height space.

A remote control is a popular accessory. See some of the important product and safety features below.

Retractable thrusters cause no drag

If you have a performance boat, sail, or power, and you're worried about the smallest amounts of drag, a retractable thruster is a perfect solution for you.

Sleipner's retractable thrusters work with all types of propulsion systems – DC, AC, and hydraulic – and can be installed in the bow and the stern of the boat. Available as standard (on/off) or PRO™ with variable speed control extending from 80 kg to 650 kg of thrust.

Like all Sleipner products, the retractable thrusters are made with high safety standards. Safety is important in product design, from build quality to ease of installation, to ensure long-term reliability.

There are three versions of the retractable thrusters, one designed to be directly molded in and two designed to be mounted on a flange. The flange can be a mold-in base from Sleipner, or boat builders can use materials suitable for their hull or as part of their hull design.

The flange-mounted models have the thruster unit placed in a casing that can be bolted to a base. This makes installing the thrusters in hulls made from different materials easier. It also simplifies series production, as it avoids the need to mix laminating and engineering jobs.

Quick deployment

The thrusters with a tunnel diameter of 185 mm use one fast and powerful actuator. In comparison, the models with a diameter of 250 mm and 386 mm have two actuators to handle the increased forces while maintaining the same exceptionally fast deployment time.

Features

- Fitted as bow and/or stern thruster

- Quiet operation

- Plug & Play S-Link™ two way communication control cable wiring

- Motor assembly rigid mounted on retracting casing: no moving parts during retracting operation

- Compact size

- Reliable retracting mechanism avoids sticking

- Fast deployment

- Easy-to-use control panel with status feedback from thruster

- Available as PRO with variable speed control

The retract mechanism

The unique design of the underwater mechanism has only a few, but very solid parts, contributing to the stability of the unit. The unit's design makes the thruster as compact as possible while enabling safe use of heavier motors on more powerful units. The vertical installation of the motor (SRV) reduces shock forces on the unit in extreme waves compared to motors mounted at an angle.

Properties

S-LINK™

S-Link™ is a CAN-based control system used for communication between Sleipner products installed on a vessel.

- Compact and waterproof plugs

- Keyed and color-coded connectors to ensure correct and easy installation

- Different cable lengths, extenders and T-connectors makes the system scalable and flexible to install

Q-PROP™

The Q-PROP™ has measured noise reductions of up to 75% in controlled environments. The five-bladed skew propeller reduces noise levels while maintaining exceptional efficiency. Some thruster models even see an increase in thrust power.

- The expected noise reduction in average installations: 20-40%

- Upgrade kits are available for most Sleipner thruster models with special adaptors

PRO™

A PRO™ thruster system enables you to apply only the necessary power to complete your maneuver. The variable speed control eliminates the noise associated with standard on/off thrusters.

The system also includes a practical hold-function. In a dual system (bow and stern) a single press of a button will keep you alongside the docks - making docking truly a one-person job.

Speed controlled thrusters are the best choice for joystick interaction.

INTELLIGENT POWER CONTROL

Sleipner's patented intelligent power control provides a minimal delay between drive directions to reduce wear of the mechanical parts while monitoring solenoid functions. In the case of a solenoid lock-in, the thruster will automatically stop without extra user action or controlling the main switch.

OVERHEAT PROTECTION

When high temperatures are detected, On/off thrusters are automatically shut off to prevent overheating. PRO™ thrusters with speed control provide extended run-time by derating power to maintain temperature within safe levels.

GALVANIC SEPARATION

Immersed parts exposed to seawater are galvanic isolated from the onboard electrical system, eliminating stray currents.

SEALED DRIVE LUBRICATION

The thruster gearleg is pre-filled for lifetime lubrication and sealed using a long-time mechanical seal with ceramic and carbon surfaces for ultimate security against water intrusion.

FLEXIBLE COUPLING

Flexible coupling protects the product’s driveline by compensating for minor misalignments between the shafts of the thruster motor and gearleg.

TWIN PROPELLERS

Twin propellers can provide more thrust than a single propeller system in the same tunnel diameter. We use this system in our mid-range models, where high thrust is required in small tunnel diameters. Due to the compact design and high performance, the twin models have become the thrusters of choice among boatbuilders worldwide.

| Main power | Value |

|---|---|

| Power supply | 24V DC |

| Nominal voltage | 21V DC |

| Nominal current consumption A | 340A |

| Power output at nominal voltage | 6.3kW / 8.4hp |

| Recommended fuse A | ANL 325 |

| Cold Cranking Amps (CCA) | Value |

|---|---|

| Minimum battery CCA (DIN) | 400 |

| Minimum battery CCA (SAE) | 760 |

| Minimum battery CCA (EN) | 680 |

| Alarms | Value |

|---|---|

| Alarm notification | Via the product's control device |

| Performance and features | Value |

|---|---|

| Motor cycle duty | 2 - 3 min. Duty cycle at 20°c (Ambient temperature) |

| Thrust ratings | Value |

|---|---|

| Thrust at 24V | 116kg / 256lbs |

| Thrust at 21V | 100kg / 220lbs |

| Features | Value |

|---|---|

| Intelligent Power Control | Yes |

| Q-Propeller | Yes |

| Twin Propellers | Yes |

| Sealed Drive Lubrication | Yes |

| Galvanic Separation | Yes |

| PRO - Variable Speed Control | Yes |

| S-Link | Yes |

| Flexible Coupling | Yes |

| Ceramic Seals | Yes |

| Physical properties | Value |

|---|---|

| Thruster Series | SR-series |

| Dimensions | Value |

|---|---|

| (H) Height | 243mm / 9.56in |

| (+H) Additional Height | 221mm / 8.68in |

| (L) Length | 561mm / 22.09in |

| (W) Width | 359mm / 14.14in |

| (ID) Internal Diameter | 185mm / 7.28in |

| (WD min.) Minimum Water Depth | 185mm / 7.28in |

| (RD) Retract Depth | 276mm / 10.85in |

| (RW) Retract Width | 195mm / 7.66in |

| (MW) Mould Width | 257mm / 10.11in |

| (ML) Mould Length | 483mm / 19.02in |

| (MH) Mould Height | 62mm / 2.43in |

| (CT) Cable Terminal | M8 |

| Installation capability | Value |

|---|---|

| Bow Capability | Yes |

| Stern Capability | Yes |

| Retractable Capability | Yes |

| Ideal vessel integration | Value |

|---|---|

| Typical vessel class | Motor boat, Sail boat |

| Typical vessel size | 12-17m / 35-55ft |

-

CE Declaration of conformity (Doc) - DC - thrusters

Conformity CertificateEnglishpdf -

DWG.fil SRV100/185T-24V - metadata

CAD FileEnglishdwg -

DXF.fil PPC 800

CAD FileEnglishdxf -

DWG.fil PPC 800

CAD FileEnglishdwg -

IGS.fil PPC 800 (simple version)

CAD FileEnglishigs -

Video Sleipner Technical Replacing Drive Line Seal

Installation VideosEnglishmp4 -

Product specification sheet_DC_thrusters

Product sheetEnglishpdf -

STP.fil PPC 800 (simple version)

CAD FileEnglishstp -

Joystick integration overview for Sleipner thruster systems

Service/Support ManualEnglishpdf -

Product specification sheet PPC 820_520

Product sheetEnglishpdf -

Installation Manual, SR SE Pro L&V (SRL/V-P80, SRL/V-P100)

Installation ManualEnglishpdf -

User Manual, SR Pro and SR Pro ignition protected (SRP, SRP IP)

User ManualEnglishpdf -

XT.fil SRV100/185T-24V - SRVP100 Vertical Retract 24V - open

CAD FileEnglishx-t -

STP.fil SRV100/185T-24V - SRVP100 Vertical Retract 24V - open

CAD FileEnglishstp

SRVP100 PRO™ retract bow/stern thruster 24V

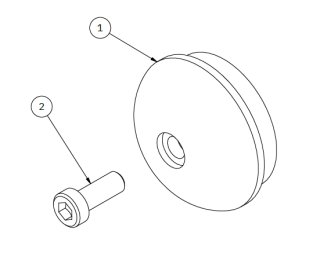

Guide to navigating spare parts

Below you will see the top-level assembly of spare part groupings available to you. If you desire a component within the presented assembly group, click on the name tag below the image to be directed to a detailed spare parts list for that assembly group. If no additional spare parts are available, it means that the current assembly group must be purchased as a whole due to service or installation requirements.

Electric motor 24V

DIN 912 - M10 x 25

DIN 125 - A 10,5

Power cable-red L=800mm

Motor cable

1 Retract mechanical SRV80/100 24V

Actuator kit 24V

2 PPC520 PRO™ power control unit

DIN 933 - M8 x 25

DIN 934 - M8

DIN 7981c M4,8x16

3 Horizontal shaft SRV 185mm

DIN EN ISO 1234 - 3,2x20

Lifting arm complete BB

Packing box

O-ring

Locking nut

Sleeve bearing Ø32 ø28 L20

Seal kit horisontal shafts

Sliding washer

DIN EN ISO 1234 - 3,2x33

Thrust washer

DIN EN ISO 1234 - 3,2x12

Shaft for sensor

4 Adapter water proof SRV

Adaptor for seals SRV sensor

O-ring Ø14x3mm

Composite shaft for SRV sensor

O-ring Ø18x3mm

DIN 125 - A 4,3

ISO 7045 - M4 x 40

ISO 7045 - M4 x 55

5 Vertical shaft SRV 185mm

Bearing seal holder

Lock washer

O-ring

Lock nut

DIN 6912 - M6 x 25

DIN 125 - A 6,4

Tool for Ball bearing mounting

DIN 471 - 25x1,2

Rotary Lip Seal

SKF 2RS1W 61805-2RS1

Bushing Drive Shaft

DIN 6885 - A 5 x 5 x 16

Flexible drive shaft

DIN EN ISO 1234 - 3,2x12

Drive shaft lower link

Locking pin

Bushing SRV joint

6 Tunnel kit for retract thruster SRV80/100

DIN EN ISO 1234 - 3,2x20

Twist ring

Ø6 x 45,5mm

Drive shaft lower link

DIN EN ISO 1234 - 3,2x12

Bushing SRV joint

Wype Ring Ø28

Turn ring

Tunnel

DIN 912 - M8 x 50

DIN 3771 - 32 x 1,5 - NBR

Sealing holder

Lifting plate

DIN 985 - M8x1,25

Locking pin

7 Anode, aluminium SE60/80/100

Anode, aluminium

Bolt - DIN 6912 - M6 x 16

8 Gearleg SE80/100 w/out propeller

DIN 912 - M8 x 55

DIN 127 - A 8

DIN 125 - A 8,4

Drive pin

Propeller washer SS2324

DIN 985 - M12x1,75

Disclaimer

Sleipner warranties the original spare parts supplied only. The installer alone has responsibility for the installation of the spare parts. Do not attempt to fit replacement parts unless you are competent. If the spare part is fitted incorrectly, Sleipner Group will not be liable for any damage resulting.

The information given in the document was correct at the time it was published. However, Sleipner Group cannot accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifications without notice. Consequently, Sleipner Group cannot accept liability for any possible differences between product and document.

-

Not necessarily. These systems typically come with a Battery Management System (BMS) that will disconnect the thruster in case of any issue with the battery (for instance, if the thruster draws more current than the BMS allows). Just imagine a sudden cut-out in the middle of a maneuver without any pre-warning.

At Sleipner, we recommend a solution with a simple, separate battery and without a disconnect BMS system (such as the lead acid bank frequently used for starting or similar). The helmsman will then be warned when the battery is getting low and feel that the thrusters are gradually losing power, which is significantly better than losing your thrusters without any pre-warning.

Disclaimer: Ensure battery/energy source is installed according to CE/ISO current rules and regulations and by licensed electricians.

-

Yes, you can, but not without taking some precautions. Sleipner produces two product lines of thrusters that will work well with high-capacity batteries and one product line which should be used with caution in combination with LiFePO4, Lithium, Li-ion, or similar batteries, which may be capable of delivering higher voltage under load than traditional batteries (such as lead-acid, AGM, gel or similar).

- All Sleipner proportional thrusters will work well with Li-ion or LiFePO4 batteries, as the included PPC unit will control the output voltage to a safe level for the thruster. Make sure, though, that you actually get a good battery intended for maritime use. NB - make sure you have the latest embedded software installed.

- All Sleipner eVision thrusters have built-in functionality to limit the maximum voltage delivered to the thruster. Again, make sure your battery is intended for maritime use.

- Traditional DC on/off thrusters may be damaged or have a reduced life expectancy if operated at voltage levels outside their specifications.

Disclaimer: Ensure battery/energy source is installed according to CE/ISO current rules and regulations and by licensed electricians.

- All Sleipner proportional thrusters will work well with Li-ion or LiFePO4 batteries, as the included PPC unit will control the output voltage to a safe level for the thruster. Make sure, though, that you actually get a good battery intended for maritime use. NB - make sure you have the latest embedded software installed.

-

Yes. Most engineers would tell you that it is not ideal for connecting the bow thrusters to a service bank protected by a Battery Management System. Thrusters are heavy consumers, and they may create sudden peaks in current draw, which again may cause the BMS to disconnect the batteries if the thruster draws more current than allowed. If this happens in the middle of a maneuver, you would be left without thrusters and may lose control of the boat.

Hence, Sleipner recommends that the thrusters be connected to a separate battery bank (that is not lithium) without a Battery Management System that can disconnect the batteries (and consequently the thrusters).

Disclaimer: Ensure battery/energy source is installed according to CE/ISO current rules and regulations and by licensed electricians.

-

This is a unique patented Sleipner safety feature supplied with all standard (on/off) DC electric Sleipner thrusters. The IPC functionality provides two unique features:

1) It will detect "flapping" of the solenoid (typically caused by badly charged batteries that are subject to a huge current draw and voltage drop when the thruster motor is engaged), and will stop trying to run the thruster, preventing excess solenoid contact tip wear and dramatically reducing the risk for a weld-in situation of the solenoid. A 'weld in' (run away) situation is when a thruster continues operating without a signal from the operator at the control panel.

2) Even if the solenoid has a weld-in situation, which even with the IPC prevention actions is still possible, as all mechanical switches can weld-in at a point, the unique IPC function will STOP THE THRUSTER, without active action by the operator. This will give the operator time to locate and Select OFF on the thruster system Isolation/Main Switch.

-

Sleipner recommends that the thrusters are connected to a battery bank that is not protected by a Battery Management System (BMS). Typically this means lead-acid, AGM, gel, or similar kinds of batteries. This is important because thrusters draw a lot of currents quickly, and the high amp draw may lead the BMS system to think that there is an issue with the system and consequently disconnect the batteries from the circuit, in which case you would lose maneuverability.

If you have Lithium batteries powering your thrusters, the best advice we can give you is to check the actual voltage measured on the thrusters during operation. Sleipner thrusters are designed to operate within a specific voltage range, and as long as you are within these boundaries, it doesn’t matter for the thruster if the current is delivered by this or that battery pack.

It may also be a very good idea to check the actual current drawn from the battery during full power at the thruster to see that you are not at the limit for the BMS to avoid sudden loss of maneuverability if the BMS disconnects the battery.

With installations where the battery pack is far from the thruster, the higher voltage delivered by LiFePO4 or similar batteries might not be a problem as you will experience a voltage drop through the long cables.

Always make sure you measure your voltage on the thruster to avoid the risk of early thruster wear.

As battery tehcnology is changing rapidly, we always recommend consulting a professional battery supplier.

Disclaimer: Ensure battery/energy source is installed according to CE/ISO current rules and regulations and by licensed electricians.

-

A legacy that commits

We’ve lived and worked with the unruly sea for a hundred years. That’s why we develop important features that enables a boat to handle the sea better – that enable you to enjoy your boat, at anchor and at full speed. That is why you wanted a boat, isn’t it?

-

Beautiful engineering

The technology in our solutions is world-class. We know, because we’ve developed it ourselves, just as we manufacture every solution, and follow them until their fixed to a hull, ourselves. This meticulous attention to detail is why your day out always will be better with a Sleipner aboard.

-

Worldwide service

We take pride in our solutions’ function throughout their lifespan. So, we never really let them out of sight, even when they’ve left for distant shores. Our global network is there to ensure continuous optimal function. You know what you get with a Sleipner, today and tomorrow.